SmartEAM helps to understand that some equipment is likely to fail.

The technologies is used:

- Equipment failures;

- Out-of-range parameter values;

- Creates a predictive work request.

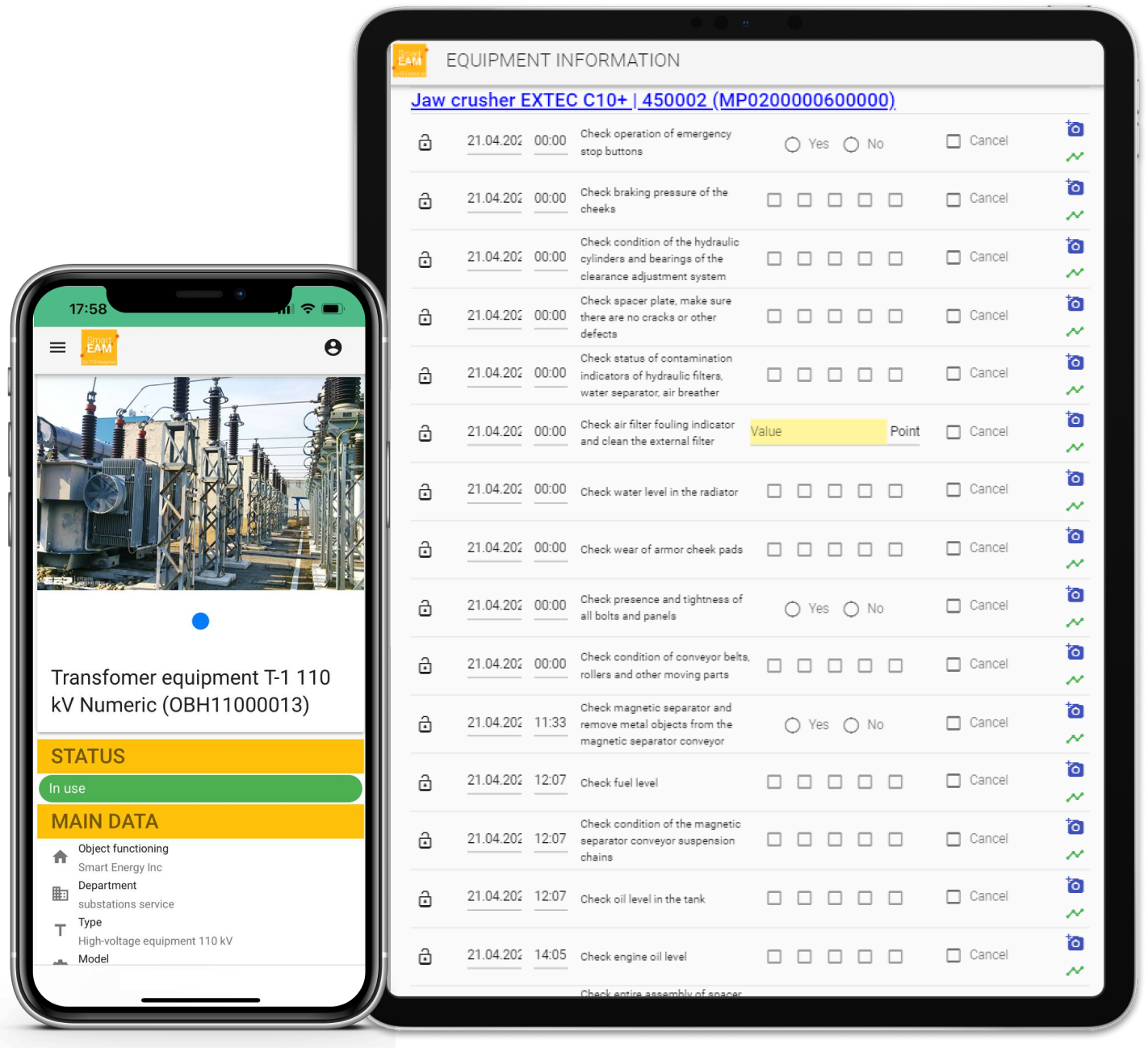

You don’t have to wait until your equipment fails. During inspections, technicians examine the equipment and collect the key data. Then, based on the parameter values, the system builds trends.