Maintenance approach. Mobile applications and QR-coding equipment

Production management and maintenance are the most important functions in a modern enterprise, which with confidence can be called an achievement in the field of automation of business processes. Those organizations that have already begun to introduce innovative technologies have seen results in practice. They understand the key trends that can change the industry in the coming years beyond recognition. Yesterday it was hard to imagine that thermostats and coffee makers will have an Internet connection, and today Gartner, an analytical company, is talking about 6.4 billion devices connected to the Internet of things.

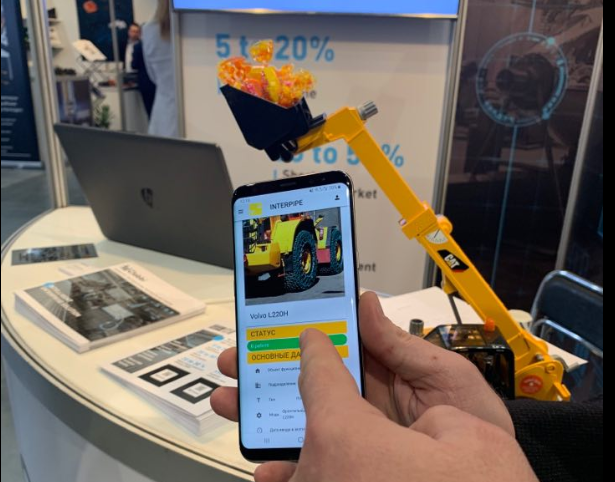

Studies of other global analytical companies such as Forrester and Verdantix show tangible benefits for organizations that invest in software systems and automate business processes aimed at servicing their assets. Benefits include an increase in technical availability of equipment by 5–20%, a decrease in maintenance costs from 10 to 40%, a decrease in response time to maintenance by 25%, an increase in OEE from 20 to 30%.

Technology

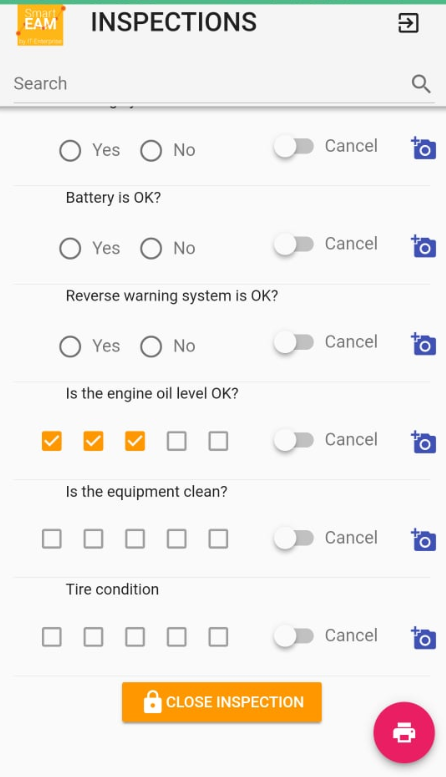

Traditional maintenance management tools and methods are now widely used in most enterprises. With the advent of mobile applications that easily integrate with existing business processes, comparing the accuracy of the data with the usual paper-and-pencil documentation or an Excel file simply fade in comparison with the possibilities that are opened when using mobile applications.

Of course, software maintenance is not a new idea. Even existing CMMS-systems successfully solve such issues, but modern solutions are more complex, provide better integration with outdated and / or existing business processes and play a more important role in modern organizations.

More and more companies prefer to run applications in the cloud to simplify access and improve interaction between people in the enterprise. Moreover, thanks to machine learning capabilities, complex applications are able to analyze data and, based on them, offer performance information and recommend ways to eliminate detected deviations. Thanks to predictive BI analytics, it is possible to prevent the impact of negative phenomena, such as an unplanned stop or an unexpected breakdown, even before the moment they occur.

Mobility

Mobile devices today are more mobile than ever before, and perform a lot of complex and complex tasks with installed applications. Any smartphone can now perform a dual function, for example, as a QR-tag scanner or a tool for creating service requests.

Mobility has changed the way many service technicians work. For example, from fulfilling orders for work with clients in the field, requesting parts for a special order with a few clicks of the mouse, to fast communication between all employees of the company.

Previously, for example, in order to find out if the necessary part or consumables was in stock, a phone call or even a trip was needed before receiving the actual information. The staff who provided assistance to other technicians and field service representatives spent a lot of time in the field to provide the requested information. Now mobile devices allow you to achieve almost any desired result, and you do not need to make a phone call.

Automation

Linking to the workplace for data entry is no longer required; employees can move freely around the production area without losing precious time on manual data entry. The service technician becomes more efficient, productive and mobile.

Today, in order to enter accurate and current data, to obtain a list of the necessary information about the equipment, it is enough to scan a QR-tag placed directly on the equipment using a smartphone or tablet. What used to take minutes or even hours, depending on the complexity of the task, now takes only a few seconds.

Management of production assets and their maintenance are functions that in a certain sense lag behind in terms of technology development and automation. Companies can not operate without the main production equipment, so relying on unconfirmed methodologies is not considered appropriate. But given the achievements that have already begun to actively develop in various industries, it becomes clear that the competitive advantage in the field of equipment and maintenance management lies in the application of these technologies. The SmartEAM slogan in this direction is “Use innovative technologies today to be competitive tomorrow”

The basis for automating business processes in modern methodologies for the maintenance and management of equipment in EAM systems is QR technology marking equipment. Using mobile solutions of automatic data collection in combination with QR-marking equipment, SmartEAM platform minimizes (or even eliminates) manual data entry, significantly improves the accuracy of data acquisition, increasing productivity, reducing maintenance costs. The introduction of the SmartEAM platform using mobile applications in conjunction with the QR-marking equipment is one of the most important decisions that will affect the development of your company in the near future.