Condition Monitoring (CBM)

In recent years, there has been a major trend towards the transition of manufacturing enterprises from corrective MRO methods to predictive maintenance. This approach has already proved effective in boosting equipment effectiveness and reducing maintenance costs.

Equipment condition monitoring plays a key role in the transition to predictive maintenance and Industry 4.0. Between 2020 and 2025, the market of equipment maintenance with Industry 4.0 tools is expected to at least triple and reach $12 bln.

Higher production performance is achieved through better organization of the maintenance team’s work and more efficient addition, processing and analysis of condition monitoring data.

The basic principles of organizing equipment condition monitoring in SmartEAM provide a guaranteed improvement in equipment effectiveness with minimum costs of data addition, processing and further analysis.

System functionality:

- Schedule equipment inspections, create shift tasks for technicians;

- Create a list of condition parameters for each type of equipment;

- Automated registration of equipment inspection results and work request generation;

- Lower labor costs of equipment inspections;

- Inspection confirmation and time logging;

- Collection, aggregation and analysis of inspection results for further use in planning maintenance jobs and forecasting residual equipment resource;

- Automated report generation and creating dashboards on inspection results and equipment condition.

Tools:

- Operation statistics;

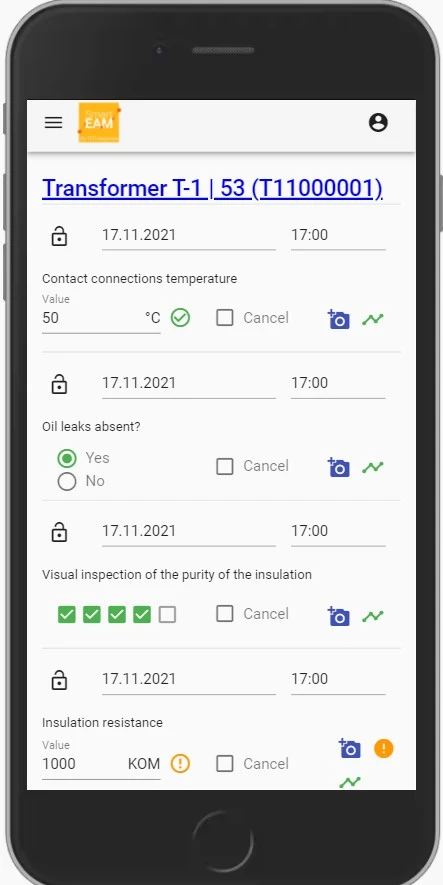

- Inspection cards;

- Mobile and web interface for condition monitoring;

- Analytical reports;

- Interactive dashboards;

- Inspection connectivity with work request generation;

- Inspection confirmation and time logging.